Doubel Combustion Chamber

All Incinerators are Doubel Combustion Chamber with One Fuel Burner Each. After Burner Technology for Completely Combustion and Cleaner World.

Read MoreHigh Temperature Incineration

Temperature Range 800 Degree to 1200 Degree in Combustion Chamber. Temperature Thermocouple Monitor and Controller. High Quality Fire Brick and Refactory Cement.

Read MoreGet Lastest News

There are latest incinerator news like technical, public news, business tender for medical waste incinerator,animal incineration, pet cremation

Read MoreNanjing Clover Medical Technology Co.,Ltd.

Email: sales@clover-incinerator.com | Tel: +86-25-8461 0201

Regular model incinerator for market with burning rate from 10kgs to 500kgs per hour and we always proposal customer send us their require details, like waste material, local site fuel and power supply, incinerator operation time, etc, so we can proposal right model or custom made with different structure or dimensions.

Incinerator Model YD-100 is a middle scale incineration machine for many different usage: for a middle hospital sickbed below 500 units, for all small or big size family pets (like Alaskan Malamute Dog), for community Municipal Solid Waste Incineration, etc. The primary combustion chamber volume is 1200Liters (1.2m3) and use diesel oil or natural gas fuel burner original from Italy.

Latest Post

Sustainable Animal Waste Incineration Solutions in Africa: HICLOVER Expands Its Reach

Sustainable Animal Waste Incineration Solutions in Africa: HICLOVER Expands Its Reach

[City] C [Date] C The safe disposal of animal waste has become a growing concern across Africa, particularly in regions where livestock farming, poultry production, and veterinary services are essential to local economies. Outbreaks of animal-borne diseases, combined with strict requirements for sanitary waste disposal, have pushed governments, veterinary authorities, and NGOs to adopt modern incineration technology.

The HICLOVER TS Series has proven to be an effective solution for animal waste management. Designed to handle carcasses, veterinary sharps, and by-products from slaughterhouses, the TS100 (100 kg/hour) and TS200 (200 kg/hour) incinerators deliver high-temperature destruction with complete sterilization. The dual-chamber system ensures that animal remains are reduced to sterile ash, preventing the spread of pathogens and controlling odors.

To address environmental concerns, HICLOVER offers advanced smoke emission control packages, including wet scrubbers, activated carbon filters, and baghouse filtration. These features make the technology suitable for donor-supported agricultural and veterinary health programs, aligning with international biosecurity guidelines.

“Animal waste incineration is a critical component of public health and food safety across Africa,” said a spokesperson for HICLOVER. “Our containerized and mobile units can be deployed directly at poultry farms, veterinary hospitals, and agricultural centers, ensuring immediate and safe disposal of animal waste.”

From poultry farms in Nigeria and Kenya to veterinary hospitals in Cameroon and Tanzania, HICLOVER incinerators are helping safeguard communities, protect livestock industries, and reduce environmental risks.

For specifications and project support:

www.hiclover.com

sales@hiclover.com

High-Capacity Medical Waste Incineration Solutions in Malawi and Southern Africa

High-Capacity Medical Waste Incineration Solutions in Malawi and Southern Africa

Growing Demand for Safe Waste Treatment

Across Malawi and neighboring Southern African countries, the expansion of medical research institutions, teaching hospitals, and regional clinics has created a pressing demand for reliable medical waste incinerators. These facilities generate diverse hazardous waste streams—syringes, infusion sets, contaminated plastics, and laboratory samples—that require high-temperature destruction to meet both local and international environmental standards.

Traditional waste disposal practices such as open burning or uncontrolled landfilling no longer meet the requirements of modern healthcare. Institutions are therefore seeking professional incineration systems with capacities up to 200 kg per hour, capable of processing large volumes of waste on-site in a safe and sustainable manner.

Why Choose the HICLOVER TS200?

The HICLOVER TS200 medical waste incinerator has been specifically engineered for high-demand facilities in regions like Malawi. With a burn rate of 200 kg/hour, it is ideally suited for research institutions, district hospitals, and universities that require consistent throughput and compliance with international standards.

Key Technical Features

-

Primary Combustion Chamber: 1,980 liters with high-grade refractory lining to withstand continuous operations.

-

Secondary Combustion Chamber: 800 liters, maintaining ≥1100°C with a minimum 2-second retention time for flue gases, ensuring destruction of dioxins and furans.

-

Fuel Flexibility: Operates on diesel, natural gas, or LPG depending on local availability.

-

PLC Control System: Automated ignition, temperature monitoring, and air distribution for operator safety and efficiency.

-

Emission Control Options:

-

Wet Scrubber System for acid gas removal (HCl, SO₂).

-

Secondary Wet Scrubber with cooling, washing, and defogging.

-

Advanced Package with quench tower, activated carbon dosing, and baghouse filter for donor-funded projects requiring strict compliance.

-

Relevance to Malawi and Southern Africa

-

Urban Centers (Lilongwe, Blantyre): Hospitals and labs require on-site incinerators to manage daily waste safely.

-

Rural and District Clinics: Containerized versions of TS200 offer rapid deployment and ease of operation in remote areas.

-

Research Facilities: High-capacity incinerators ensure that sensitive biomedical samples are destroyed without risk of contamination or reuse.

-

Donor-Supported Projects: Many international health initiatives in Southern Africa mandate WHO-compliant waste treatment, which TS200 can deliver with optional emission control packages.

In local context:

“Katika Malawi, mahitaji ya vifaa vya kisasa vya kuchoma taka za hospitali yanaongezeka haraka”

(Swahili: In Malawi, the demand for modern medical waste incinerators is rapidly increasing).

Conclusion

For Malawi and Southern Africa, the HICLOVER TS200 incinerator represents a robust, high-capacity solution to medical waste challenges. With its 200 kg/hour throughput, dual-chamber high-temperature system, and advanced smoke emission controls, it delivers a reliable answer for hospitals, research institutions, and health programs aiming for international compliance and sustainable waste management.

For specifications and procurement support:

www.hiclover.com

sales@hiclover.com

HICLOVER Medical Waste Incinerators for Afghanistan’s Expanded Immunization Program

HICLOVER Medical Waste Incinerators for Afghanistan’s Expanded Immunization Program

Safe medical waste management has become a critical priority for Afghanistan, particularly within the National Expanded Program for Immunization (NEPI). With vaccination campaigns generating thousands of sharps, used vaccine vials, and contaminated packaging every day, the need for reliable treatment equipment is urgent. UNICEF’s recent assessment highlighted that open burning and burial remain widespread practices, posing risks to health workers and communities.

To address these challenges, five new incinerator units are being deployed at regional hubs in Kandahar, Nangarhar, Herat, Balkh, and Paktya, supporting more than 1,500 healthcare facilities nationwide.

Why HICLOVER Incinerators Are Chosen

HICLOVER provides dual-chamber, diesel-fired incinerators specifically engineered for healthcare waste. The equipment is designed to handle Afghanistan’s on-the-ground realities—remote locations, limited technical capacity, and the need for safe and simple operations.

Key technical features include:

-

Processing Capacity: 30–35 kg/hour in Paktya and 40–50 kg/hour in Kandahar, Nangarhar, Herat, and Balkh.

-

Combustion System: Dual chambers with 850°C in the primary chamber and ≥1100°C in the secondary chamber, ensuring full pathogen destruction.

-

Residency Time: ≥ 2 seconds in the secondary chamber to minimize harmful emissions.

-

Construction: Heavy-duty refractory lining (≥115 mm, 65% Al₂O₃) for long service life.

-

Non-Combustible Waste Deformation: Capable of treating glass syringes, metal sharps containers, and ampoules to achieve safe deformation.

-

Safety & Compliance: Equipped with sealed access doors, automatic alarms, insulated high-temperature surfaces, and noise levels ≤ 85 dBA.

Environmental and Emission Control

To comply with international emission standards, each incinerator is supplied with:

-

12-meter stainless steel chimney with sampling ports for monitoring.

-

Wet scrubbing system (optional) including spray tower and demisting stage for acid gas removal.

-

Batch feeding system with airtight refractory-lined doors to prevent smoke leakage.

This design minimizes environmental impact while offering flexibility depending on Afghanistan’s regulatory framework.

Training, Manuals, and Maintenance

HICLOVER recognizes that sustainable success depends on capacity building. Each installation includes:

-

On-site and remote operator training (waste segregation, feeding, ash removal, emission monitoring).

-

Operation and service manuals in English, Dari, and Pashto.

-

Full set of spare parts for two years of operation.

-

One-year warranty with local reseller support for preventive maintenance.

These measures ensure that Afghan health workers can independently operate and maintain the equipment long after commissioning.

Strategic Impact for Afghanistan

The deployment of HICLOVER incinerators at NEPI’s regional sites will:

-

Replace unsafe disposal methods such as open burning.

-

Strengthen Afghanistan’s compliance with WHO guidelines for immunization waste.

-

Provide safer working conditions for health staff handling 400 safety boxes and 1,000 vials daily at each site.

-

Establish a scalable model for environmentally responsible healthcare waste treatment across the country.

afghanistan medical waste incinerator project

dual chamber diesel incinerator for NEPI Afghanistan

HICLOVER incinerator Kandahar Nangarhar Herat Balkh Paktya

healthcare waste incineration system for immunization campaigns

UNICEF supported incinerator project afghanistan

incinerator with wet scrubber for infectious waste Afghanistan

Learn More

For reliable, CE-certified solutions to healthcare waste management, contact HICLOVER today:

-

Website: www.hiclover.com

-

Email: sales@hiclover.com

-

WhatsApp: +86-13813931455

HS CODE 84178050 for Waste Incinerators

HS CODE 84178050 for Waste Incinerators C Understanding Customs Classification with HICLOVER

When importing or exporting incinerators, one of the most important requirements at international customs clearance is the correct HS CODE declaration. For HICLOVER medical waste and solid waste incinerators, the applicable HS CODE is 84178050. Many overseas buyers are unfamiliar with the specific classification, so they often search online for the right code when preparing to import incinerators for hospitals, clinics, petroleum camps, or industrial facilities. By understanding the HS CODE system, buyers can save time, reduce customs delays, and ensure smooth international trade.

What is HS CODE 84178050?

HS CODE stands for “Harmonized System Code,” an international nomenclature developed by the World Customs Organization (WCO). It standardizes the classification of goods across borders.

-

84178050 specifically refers to industrial or laboratory incinerators for waste treatment, typically diesel-fired, gas-fired, or dual-fuel units.

-

In some countries, this is described as “Industrial furnaces and ovens, including incinerators, not elsewhere specified”.

-

In others, it may appear as “Other combustion or waste treatment equipment”.

For example:

-

In China, HS 84178050 is categorized under “Industrial or laboratory incinerators, including waste incinerators.”

-

In the European Union, it may fall under “Industrial furnaces and ovens; incinerators for waste treatment.”

-

In the United States, the import system (HTS Code) lists similar descriptions, sometimes with extended digits for sub-classification.

Although the description wording differs slightly by country, the number 84178050 (or its extended local version) remains the global reference for waste incineration equipment.

Why HS CODE Matters for Buyers

Incorrect HS CODE declaration can lead to:

-

Delays at customs clearance.

-

Incorrect import duties or tariffs being charged.

-

Possible rejection of shipments or additional documentation requests.

For buyers of HICLOVER incinerators, knowing and using 84178050 ensures that your hospital waste containerized incinerator (for example, a 100 kg per hour unit), your mobile incinerator for rural clinics and camps, or even larger containerized systems for African petroleum camps, will be correctly identified and taxed under the proper tariff category.

HICLOVER Incinerators and Global Export

As a leading manufacturer, HICLOVER has supplied incinerators worldwide C including to Africa, Asia, the Middle East, and international organizations such as the United Nations and World Bank projects. Export-ready models include:

-

Hospital Waste Containerized Incinerators (100C200 kg/hr): designed for hospitals and clinics, dual-chamber, PLC controlled, with optional wet scrubbers.

-

Mobile Incinerators for Rural Clinics and Camps (30C100 kg/hr): portable, containerized or trailer-mounted for fast deployment in field hospitals and refugee camps.

-

Containerized Incinerators for Petroleum Camps (300C500 kg/hr): high-capacity units for solid waste treatment in oilfield and mining base camps, with Italy-made burners and intelligent fuel-saving systems.

All exports are declared under HS CODE 84178050, ensuring consistency and compliance with international trade rules.

Supporting Buyers with Documentation

HICLOVER provides full export support:

-

Commercial invoices with HS CODE clearly declared.

-

Certificates of origin where required.

-

CE and ISO compliance certificates for technical and environmental standards.

-

Spare parts lists and technical manuals for after-sales support.

For buyers in Africa, the Middle East, or Asia, our experience with customs declarations helps avoid misunderstandings. For example, even if a buyer searches using terms like “industrial furnace HS code” or “hospital incinerator import code”, they will be directed to the correct HS CODE 84178050 C the classification for our incinerators.

Learn More

For details on HICLOVER’s containerized and mobile incinerators, as well as guidance on HS CODE declarations, visit:

Or contact us directly:

Website: www.hiclover.com

Email: sales@hiclover.com

Mobile (WhatsApp): +86-13813931455

China

-

HS CODE: 84178050

-

Chinese Description: (Industrial or laboratory incinerators, including waste incinerators)

-

Application: Used for all types of waste incinerators (medical, animal, solid waste). This is the standard code HICLOVER declares when exporting from China.

European Union (EU)

-

HS CODE: 84178050 (CN Code under TARIC system)

-

EU Description: Industrial furnaces and ovens, including waste incinerators, not elsewhere specified

-

Notes: EU sometimes extends the digits (e.g., 8417.80.50.00) for tariff purposes. This code is widely recognized for hospital waste incinerators and containerized models imported into Europe.

United States (USA)

-

HTS Code: 8417.80.50.00

-

US Description: Industrial or laboratory furnaces and ovens, including incinerators, not elsewhere specified or included

-

Notes: The HTS (Harmonized Tariff Schedule) is the US equivalent of the HS system. Importers of medical waste incinerators must use this code when filing customs entry documents.

Africa (Common Examples)

Nigeria

-

HS CODE: 84178050 (applies under ECOWAS customs system)

-

Description: Waste incinerators, dual chamber, containerized or stationary.

-

Notes: Nigerian Customs accepts the same WCO HS code structure; tariff may vary under ECOWAS CET.

Kenya

-

HS CODE: 84178000 (simplified, sometimes aggregated without last two digits)

-

Description: Industrial and medical waste incinerators.

-

Notes: Often linked to donor-funded hospital procurement (WHO, UNDP).

South Africa

-

HS CODE: 84178050

-

Description: Industrial furnaces, ovens and incinerators.

-

Notes: Listed under SARS customs tariff; recognized for mobile and containerized units.

Why This Matters for HICLOVER Buyers

By knowing the correct HS CODE 84178050, customers importing HICLOVER containerized incinerators ― whether a hospital waste containerized incinerator 100 kg per hour, a mobile incinerator for rural clinics and camps, or high-capacity models for solid waste treatment in petroleum camps ― can:

-

Avoid delays at customs clearance.

-

Ensure correct tariffs and duties.

-

Prevent shipment reclassification or penalties.

HICLOVER provides all export documentation with the HS CODE clearly declared, along with CE and ISO certificates to meet international compliance standards.

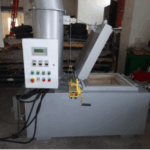

HICLOVER TS50 PLC Animal Waste Diesel-Fired Incinerator Top Loading

HICLOVER TS50 PLC Animal Waste Diesel-Fired Incinerator

1. General Description

The HICLOVER TS50 PLC is a medium-sized, high-temperature diesel-fired incinerator designed for the safe destruction of animal waste, pathological waste, and other organic materials. Built to ensure efficient, environmentally compliant combustion, this model minimizes emissions while providing reliable performance. It is ideal for veterinary clinics, research laboratories, livestock farms, and slaughterhouses.

2. Technical Specifications

-

Model: HICLOVER TS50 PLC Top Loading

-

Type: Diesel-fired, dual-chamber incinerator

-

Waste Types: Animal waste, organic waste, pathological waste, medical by-products

-

Loading Capacity: 75 kg/batch

-

Burn Rate: Up to 50 kg/hour (depending on waste composition and operating conditions)

-

Combustion Method: Controlled air incineration with optimized airflow design

3. Construction Materials

-

Primary Chamber: High-grade steel structure, fully refractory-lined

-

Refractory Lining: Minimum 180 mm thickness in both chambers for thermal stability

-

Primary Chamber Operating Temperature: 850°C C 1000°C

-

Secondary Chamber: Advanced thermal oxidation design

-

Secondary Chamber Operating Temperature: 1100°C C 1300°C

-

Residence Time: Minimum 2 seconds for complete destruction of emissions

-

Exterior Body: Stainless steel finish with anti-corrosion treatment

-

Insulation: High-efficiency ceramic insulation to minimize heat loss

4. Burner System

-

Burner Type: Diesel-fired automatic burners, multi-stage operation

-

Fuel: Diesel (optional dual-fuel configuration available)

-

Fuel Consumption: 11C15 liters/hour (average, based on waste type)

-

Ignition: Fully automatic, with fail-safe shutdown features

-

Air Supply: Forced draft system for optimized combustion efficiency

5. Emission Control

-

Fully compliant with international environmental standards

-

Secondary chamber ensures smoke and odor reduction

-

Optional dry or wet scrubber units available for enhanced particulate and acid gas control

6. Control and Monitoring Systems

-

Control Panel: PLC-based, with automation for burners, safety, and temperature regulation

-

Temperature Monitoring: Dual thermocouples (primary and secondary chambers)

-

Alarms: Visual and audio alarms for temperature deviations and system faults

-

User Interface: Digital touch display with operational controls and diagnostics

7. Loading and Ash Removal

-

Loading: Manual top-loading with crank hinge (hydraulic options available)

-

Ash Removal: Removable collection tray for simplified handling

8. Safety Features

-

Automatic shutdown on over-temperature conditions

-

Pressure relief valves for chamber overpressure protection

-

Manual and automatic emergency stop functions

9. Fuel Efficiency

-

Designed for reduced fuel usage through optimized combustion

-

Combustion efficiency over 95% ensures clean burning and reduced operating costs

10. Optional Features

-

Adjustable chimney height, stainless steel lined

-

Dual-fuel options (diesel + LPG or natural gas)

-

Advanced scrubber or filtration systems for stringent emission compliance

11. Dimensions and Weight

-

Combustion Chamber Volume: 0.75 m3

-

Overall Dimensions (L x W x H): 2300 x 1600 x 4680 mm (assembled)

-

Weight: Approx. 3000 kg depending on configuration

-

Door Size: 990 x 920 mm

-

Steel Thickness: 3 mm reinforced shell

-

Burners: 2 units

-

Electrical Supply: 230V

-

Operating Footprint: ~24.4 m2

12. Compliance and Certifications

-

Certified under ISO 9001 and CE standards

-

Fully aligned with environmental and healthcare safety regulations

13. Warranty and Service

-

Warranty: 12 months from installation

-

Support: Regional service availability, spare parts supply, and technical training packages

This revised document highlights:

-

The HICLOVER TS50 PLC name for keyword association.

-

Core technical features: dual chamber, PLC control, refractory lining, emission control systems.

-

Target industries: veterinary clinics, farms, laboratories, slaughterhouses.